Wooden H20 Beam Timber Slab plywood formwork

High-quality H20 beams plywood for formwork

$7.00$6.50

H20 beam for sale

The H20 wooden beam stands as a cornerstone in modern construction, offering an optimal blend of strength, versatility, and sustainability. Engineered to meet rigorous industry standards, this innovative beam design has revolutionized formwork systems, roofing structures, and various load-bearing applications. Its distinctive "I" cross-section efficiently distributes loads, maximizing strength while minimizing material usage. This document provides a comprehensive overview of the H20 beam, exploring its specifications, applications, advantages, and technical parameters.

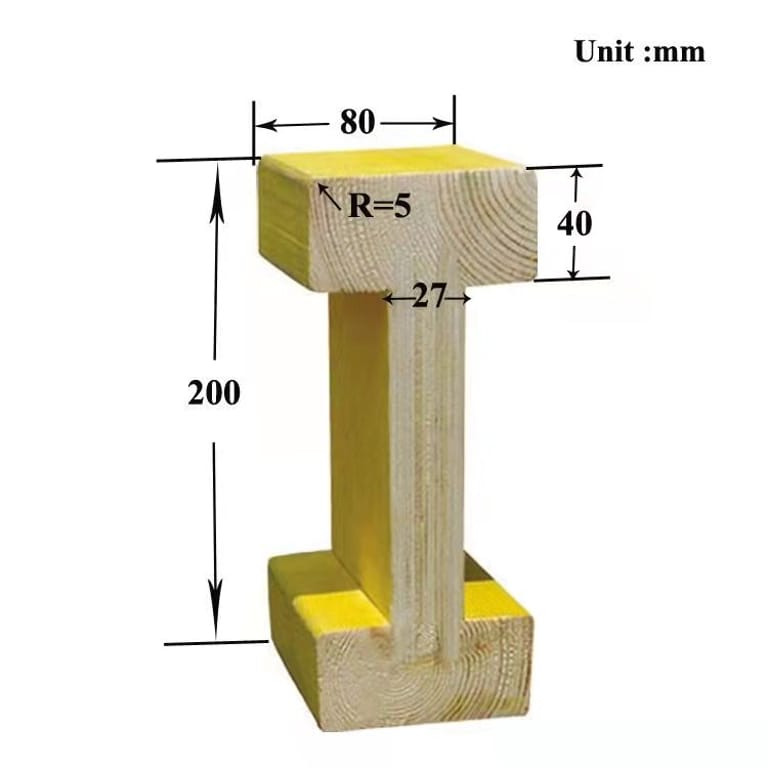

H20 beam dimensions

Design and Structure

wooden H20 beam features a unique I-shaped cross-section composed of three primary components:

- Flanges: Constructed from high-quality softwood, typically spruce or pine, with a thickness of 28mm. These provide excellent resistance to bending and shear forces.

- Web: A central plywood layer, 11mm thick, made from Douglas Fir or similar durable timber. The web connects the flanges, enhancing stability and load distribution.

- Adhesive Bond: The components are joined using waterproof phenolic resin glue, ensuring a robust and durable bond that withstands demanding construction environments.

Dimensions

- Standard Lengths: Available in lengths from 2.4m to 6m, with custom lengths available upon request.

- Cross-Section: The beam measures 200mm in height, with a flange width of 80mm, providing a consistent and reliable profile for formwork systems.

Technical Parameters

- Moisture Content: Maintained between 12% and 18%, ensuring dimensional stability and resistance to warping.

- Density: Flanges: 480-520 kg/m³; Web: 580-620 kg/m³

- Load Capacity: Capable of supporting heavy loads, with a design shear strength of 25 N/mm² and a bending strength of 28 N/mm².

- Fire Resistance: Treated with fire-retardant chemicals to achieve a Class C fire rating (EN 13501-1), enhancing safety in construction environments.

H20 beam key features and advantages

1 High Strength-to-Weight Ratio

The beam design optimizes material distribution, providing exceptional strength while remaining lightweight. This reduces handling costs and simplifies installation, making it ideal for large-scale projects.

H20 beam weight: 4.8KG/m

2 Reusability and Durability

Constructed from premium-grade timber and reinforced with waterproof adhesives, H20 beams can be reused up to 50 times with proper maintenance. This durability significantly reduces material waste and lifecycle costs.

3 Versatility

Suitable for a wide range of applications, including:

- Formwork systems for concrete slabs, columns, and walls

- Roof structures and floor joists

- Bridge construction and temporary supports

- Industrial and commercial building projects

4 Sustainability

Manufactured from FSC®-certified timber, the H20 beam supports sustainable forestry practices. Its long service life and reusability further contribute to eco-friendly construction methods.

5 Easy Installation

The standardized dimensions and lightweight design facilitate quick and efficient installation. The beams can be easily cut, drilled, and fastened using conventional tools, reducing labor time and costs.

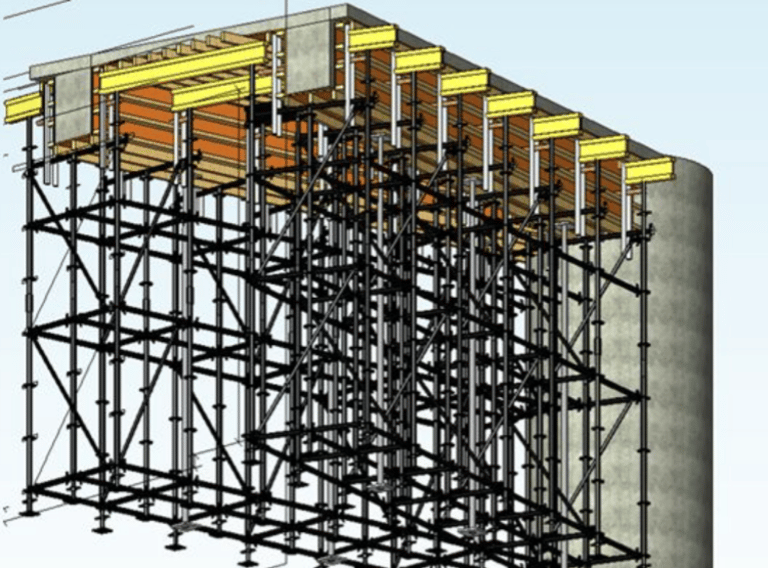

H20 beam scaffolding systems

1 Formwork Systems

H20 beams are widely used in formwork due to their uniform dimensions and high load capacity. They provide reliable support for concrete structures, ensuring precise shaping and alignment during the curing process.

2 Roofing and Flooring

As roof joists or floor beams, H20 wooden I-beams offer stable support for roofing materials and floor finishes. Their lightweight nature reduces the structural load on foundations, making them suitable for a variety of building types.

3 Temporary Structures

In construction sites, H20 beams are employed to create temporary supports, scaffolding, and access platforms. Their durability and load-bearing capacity ensure safe working environments during building and renovation projects.

4 Bridge Construction

The high strength and versatility of H20 beams make them ideal for bridge deck formwork and temporary bridge structures. They can be easily adapted to various span lengths and load requirements.

Got a specific enquiry about Zhuniu Formwork?

Why not call our team on +86 180 5453 6350 (Whatsapp&Wechat)

Product video

Package and shipment

wooden H20 beam represents a smart choice for modern construction professionals seeking a balance of performance, sustainability, and cost-effectiveness. With its exceptional strength, versatility, and eco-friendly credentials, it is an indispensable component in a wide range of building applications. Whether for formwork, roofing, or temporary structures, the H20 beam delivers reliable performance that meets the demands of today's construction industry.

For more information or to request a quote, please contact our technical sales team. We are committed to providing tailored solutions and expert support for your construction needs.

Environmental Impact

The H20 wooden I-beam aligns with green building practices:

- Renewable Resource: Timber is a renewable and biodegradable material.

- Energy Efficiency: Requires less energy to produce compared to steel or concrete beams.

- Carbon Sequestration: Timber stores carbon dioxide, reducing the carbon footprint of construction projects.