Shuttering plastic formwork : Cost-Effective Concrete Formwork choice

Shuttering wall plastic concrete formwork

$40.00$38.00

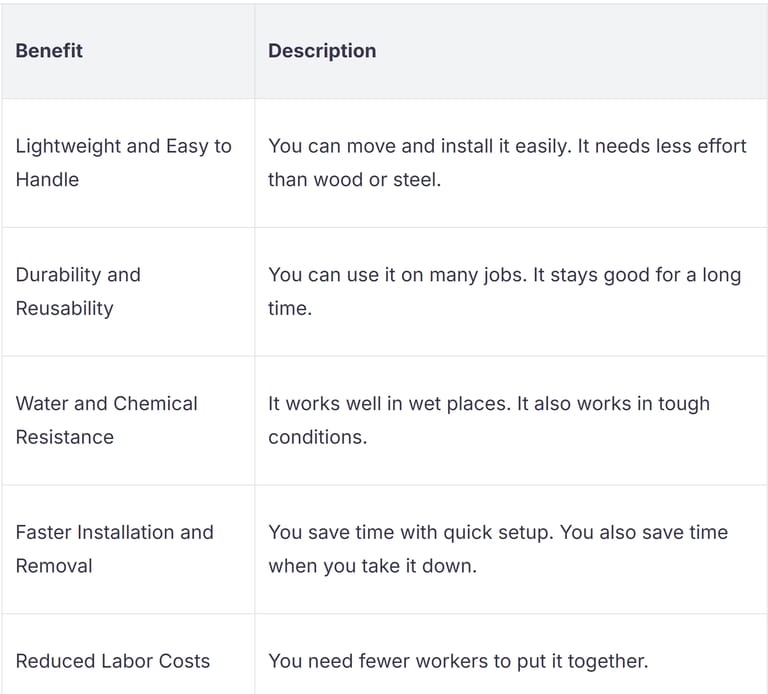

Plastic formwork helps you build concrete columns better. Wood molds can break fast. Steel molds are heavy and hard to move. Plastic formwork is strong and light. It is easy to use. You can use it more than 100 times. You can change it for different column sizes. Here are the top benefits from recent surveys:

Discover our high-quality plastic formwork for concrete walls designed for construction projects. As a leading manufacturer from China, we provide innovative solutions that enhance construction speed and reduce overall project costs. Our formwork is engineered for durability and efficiency, ensuring that construction workers can achieve optimal results while saving time and money. Explore our range of products to find the perfect fit for your construction needs.

Project savings

You want your project to cost less. Plastic formwork helps you save money. It costs about 20% less than steel formwork. You save more because you can use the panels many times. Wood formwork does not last long. Plastic panels can be used 60 to 100 times. You buy fewer panels and throw away less.

Here is a simple chart to compare materials:

Plastic formwork gives you better value for your money. You spend less fixing and replacing panels. You also save on labor because the panels are easy to move.

Plastic formwork can be reused much more than wood.

You can cut your costs by up to 60% compared to plywood and metal.

Maintenance costs go down because plastic panels stay strong and clean.

Sustainability

You help the planet when you use plastic formwork. Many panels are made from recycled plastic. Most products use 70% to 100% old plastic. This keeps trash out of landfills and gives plastic a new use.

Recycled plastic is used to make formwork panels.

Most panels have lots of recycled plastic.

You make less waste and help keep the earth clean.

You also make less construction trash because you reuse the panels. When your project is done, you can recycle the panels again. This makes your building process greener and better for the earth.

Every time you pick recycled materials, you help protect the planet for the future.

On-site construction

Plastic formwork is used in many building projects. Teams use it for tall buildings, bridges, underground work, floors, and foundations. Factories, warehouses, and city projects also use this system. Prefabricated parts need plastic formwork for good shape and quick work.

"plastic formworks are good for pouring columns. They help keep the columns the right size and shape."

Plastic formwork works in many places. You can put the panels together and take them apart fast. This helps you work well, even in wet or very hot or cold places. You pick panels that do not get damaged by water for wet sites. You pick strong panels for places with tough weather. You also check that your formwork follows building rules. This keeps your columns safe and strong.

Tall Buildings

Bridge Building

Underground Work

Floors and Foundations

Special Shapes

Factories and Warehouses

City Projects

Prefabricated Parts

Plastic formwork makes building easier and helps you build in a way that is better for the earth.

Got a specific enquiry about Zhuniu Formwork?

Why not call our team on +86 180 5453 6350 (Whatsapp&Wechat)

1. Superior Durability & Reusability

Our plastic concrete formwork is engineered with high-strength composite materials, ensuring exceptional resistance to impact, corrosion, and wear. Compared to traditional wooden or metal templates, our products can be reused up to 50+ times, significantly reducing replacement costs and material waste over the lifespan of your projects.

2. Lightweight Design for Enhanced Efficiency

Designed with lightweight properties, our formwork reduces labor intensity and installation time by 30-50%. The easy-to-handle structure allows for quick assembly and disassembly, ideal for projects with tight schedules. This efficiency translates to lower labor costs and accelerated construction timelines.

3. Environmental Sustainability

Committed to green construction, our plastic formwork is:

Recyclable: Made from eco-friendly materials that can be recycled at the end of their service life, minimizing environmental impact.

Timber-Saving: Eliminates the need for disposable wooden templates, contributing to forest conservation and sustainable building practices.

Low Carbon Footprint: Reduces energy consumption during production and transportation compared to metal alternatives.

4. Precision Engineering for Perfect Finishes

Our formwork ensures smooth, defect-free concrete surfaces with minimal need for post-processing. The high-precision molds and consistent material properties guarantee uniform dimensions, reducing rework and enhancing the aesthetic and structural quality of your projects.

5. Cost-Effective Long-Term Investment

While initial costs may seem comparable to traditional templates, the long-term savings are substantial:

Reduced Replacement Costs: Fewer replacements mean lower material expenses.

Minimal Maintenance: Resistant to water, chemicals, and UV damage, requiring little upkeep.

High Return on Investment (ROI): Proves cost-effective after just 5-8 uses, making it ideal for large-scale or repetitive projects.

Choose our plastic concrete formwork to transform your construction projects with efficiency, sustainability, and cost savings. Contact us today to discover how our solutions can elevate your next venture!

FAQ:

1.How many times can you reuse plastic formwork?

You can reuse plastic formwork more than 100 times. The panels stay strong and do not break easily. This helps you save money on every project.

2.Can you adjust plastic formwork for different column sizes?

Yes, you can adjust the panels for many sizes. The modular design lets you change the shape and fit columns from small to large.

Tip: You can use one set for many projects with different column sizes.

3.Is plastic formwork safe for outdoor construction?

Plastic formwork works well outside. It resists water and harsh weather. You can use it in rain or sun without problems.

4.Does plastic formwork help the environment?

Plastic formwork uses recycled materials. You help reduce waste and support green building. You can recycle the panels again after use.