Get cost-effective formwork solutions today!

Adjustable Column Plastic Formwork for Concrete

Durable and easy-to-use formwork system

$92.00$90.00

Product Overview

In the construction industry, finding reliable and high-performance formwork is crucial for the success of every project. Our plastic formwork is designed to meet and exceed your expectations.

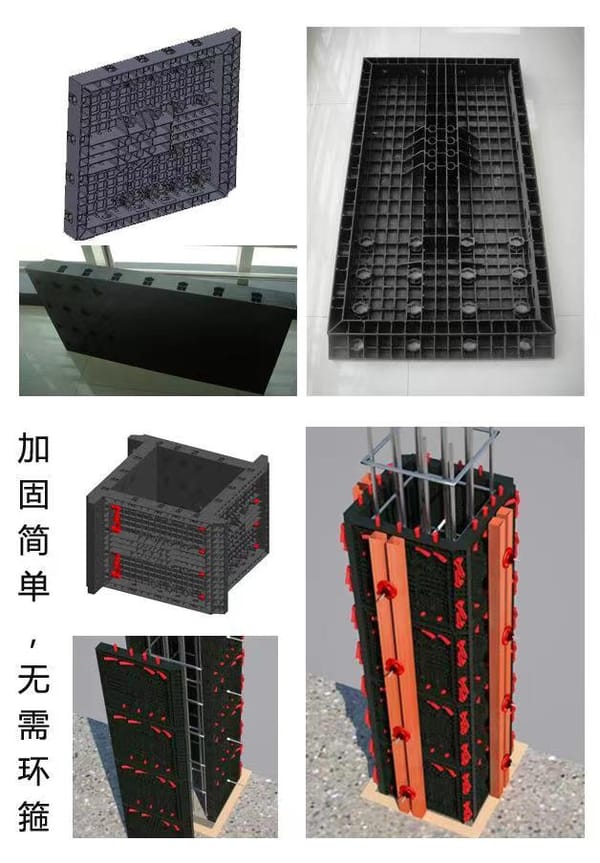

Our plastic concrete building formwork is made from advanced high-quality plastic materials through precision manufacturing techniques. It combines durability, flexibility, and ease of use, making it a perfect alternative to traditional formwork materials.

Product Detail

Material

ABS

Color

Black

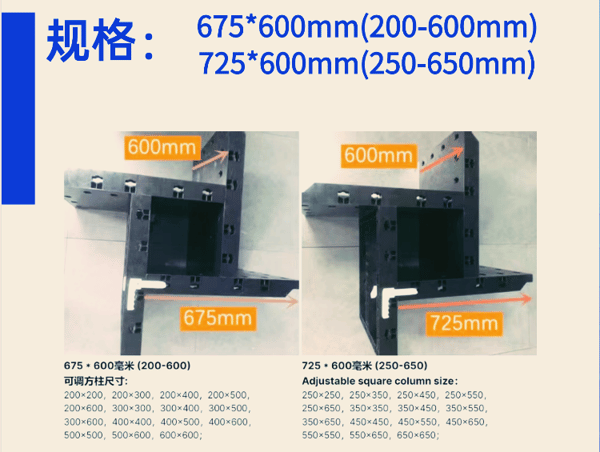

Height

600mm(23.62 in.)

Thickness

75mm (2.95 in.)

Connection

Handle

Used times

Over 100 times

Sizes

Advantages

Cost-effective:

Although the initial investment in our plastic formwork might seem comparable to some traditional options, considering its long lifespan, reusability, and low maintenance cost, it proves to be a cost-effective choice in the long run. You can use it for multiple projects, saving you the expense of frequently replacing formwork materials.

2.Eco-friendly:

Our plastic formwork is recyclable, which aligns with the growing emphasis on sustainable construction practices. By choosing our product, you are contributing to reducing waste and environmental impact in the construction industry. Unlike some wooden formwork that may end up as waste after a few uses, our plastic formwork can be recycled and reused, minimizing its carbon footprint.

3.Versatility:

It can be used in a wide range of construction projects, including residential buildings, commercial complexes, infrastructure projects like bridges and tunnels. Whether it’s for casting columns, walls, or slabs, our plastic formwork can adapt to different shapes and sizes, providing flexibility for architects and builders.

Supporting System

Got a specific enquiry about Zhuniu Formwork?

Why not call our team on +86 180 5453 6350 (Whatsapp&Wechat)

FAQ

1. What's the best formwork material for my project?

Answer: It depends on scale and reuse needs:Wooden: Ideal for small projects (5-10 reuses), low cost but high waste.

Steel: Heavy-duty for high-rises (50+ reuses), but costly upfront.

Plastic: Eco-friendly, lightweight (30-50% faster installation), pays off after 5-8 uses.

Fiberglass: For complex shapes (curves, arches) in corrosive environments.

2. How many times can plastic formwork be reused?

Answer: Our high-strength plastic formwork lasts 50-60 cycles with proper maintenance (e.g., cleaning after each use, UV protection during storage). This reduces material costs by 40% compared to wooden templates.

3. Can formwork be customized for unique concrete shapes?

Answer: Yes. Fiberglass and plastic formwork can be molded into:Curved columns for architectural designs

Tapered bridge piers

Decorative concrete textures

3D printing and CNC machining enable precision customizations.

4. How does formwork affect concrete surface quality?

Answer: High-quality formwork (e.g., steel or plastic with smooth finishes) ensures:Smooth surfaces: Reduces need for plastering (saves $1-2/㎡).

Uniform dimensions: Tolerance within ±2mm, meeting structural standards.

Fewer defects: Properly sealed formwork prevents air bubbles and honeycombing.

5. Is plastic formwork environmentally friendly?

Answer: Yes, compared to traditional materials:Recyclable: 100% of our plastic formwork can be recycled into new panels.

Timber-saving: Replaces 80% of wooden formwork use.

Low carbon: Production emits 35% less CO₂ than steel formwork.

Holds ISO 14001 environmental certification.

6. How to calculate formwork cost-effectiveness?

Example Calculation:Wooden formwork: $5/sq.m, reusable 8 times → $0.63/sq.m per use.

Plastic formwork: $20/sq.m, reusable 50 times → $0.40/sq.m per use.

Break-even point: After 5 uses, plastic becomes cheaper.

7. What safety features should formwork have?

Key Features:Load-bearing certification: Meets ASTM E136 fire resistance standards.

Anti-slip surfaces: For worker safety during installation.

Corrosion-resistant ties: Stainless steel for coastal projects.

Edge protection: Rubberized corners to prevent impact damage.

8. How long does formwork delivery take?

Answer:Standard panels: 7-10 business days (in-stock items).

Custom orders: 3-4 weeks (includes design and manufacturing).

Expedited shipping (2-3 days) available for urgent projects at additional cost.

9. What maintenance is required for steel formwork?

Maintenance Tips:Clean concrete residue with pressure washers.

Apply anti-rust paint every 6 months.

Inspect welds for cracks before each use.

Store in dry areas to prevent moisture damage.

10. Do you offer on-site installation training?

Answer: Yes, all clients receive:Free training sessions: 2-day on-site workshop for installation teams.

Video tutorials: Step-by-step guides for modular systems.

Technical hotline: 24/7 support for emergency queries.

Why choose us

1. Superior Durability & Reusability

Our plastic concrete formwork is engineered with high-strength composite materials, ensuring exceptional resistance to impact, corrosion, and wear. Compared to traditional wooden or metal templates, our products can be reused up to 50+ times, significantly reducing replacement costs and material waste over the lifespan of your projects.

2. Lightweight Design for Enhanced Efficiency

Designed with lightweight properties, our formwork reduces labor intensity and installation time by 30-50%. The easy-to-handle structure allows for quick assembly and disassembly, ideal for projects with tight schedules. This efficiency translates to lower labor costs and accelerated construction timelines.

3. Environmental Sustainability

Committed to green construction, our plastic formwork is:

Recyclable: Made from eco-friendly materials that can be recycled at the end of their service life, minimizing environmental impact.

Timber-Saving: Eliminates the need for disposable wooden templates, contributing to forest conservation and sustainable building practices.

Low Carbon Footprint: Reduces energy consumption during production and transportation compared to metal alternatives.

4. Precision Engineering for Perfect Finishes

Our formwork ensures smooth, defect-free concrete surfaces with minimal need for post-processing. The high-precision molds and consistent material properties guarantee uniform dimensions, reducing rework and enhancing the aesthetic and structural quality of your projects.

5. Cost-Effective Long-Term Investment

While initial costs may seem comparable to traditional templates, the long-term savings are substantial:

Reduced Replacement Costs: Fewer replacements mean lower material expenses.

Minimal Maintenance: Resistant to water, chemicals, and UV damage, requiring little upkeep.

High Return on Investment (ROI): Proves cost-effective after just 5-8 uses, making it ideal for large-scale or repetitive projects.

Choose our plastic concrete formwork to transform your construction projects with efficiency, sustainability, and cost savings. Contact us today to discover how our solutions can elevate your next venture!

Package