Light steel formworks:Revolutionizing formwork

light strength steel formwork

$38.00$36.00

INTRODUCE

The significance of light steel formwork lies in its ability to address some of the most pressing challenges faced by the construction industry. Traditional formwork materials such as wood and heavy steel often come with limitations in terms of weight, durability, and reusability. Light steel formwork, on the other hand, offers a host of advantages that not only enhance the construction process but also contribute to the overall quality and longevity of the structures it helps to build.

As the construction industry continues to grow and adapt to new technologies and environmental requirements, light steel formwork is expected to play an even more prominent role. In the following sections, we will delve deeper into the key advantages of light steel formwork, exploring how its light weight, high strength, and permanent reusability are revolutionizing modern construction practices.

Design Concept:

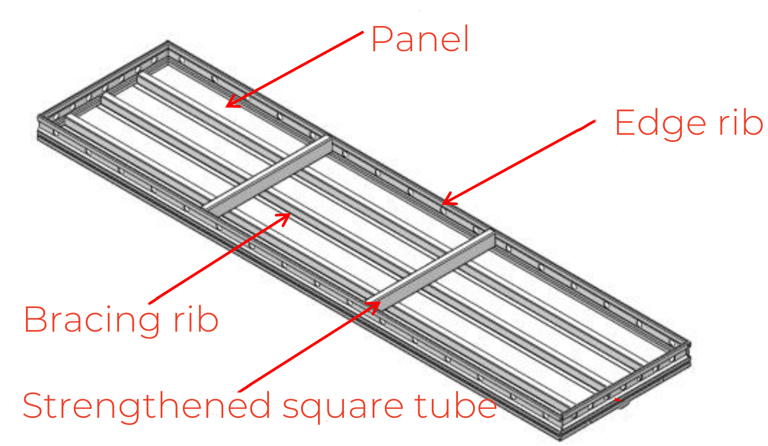

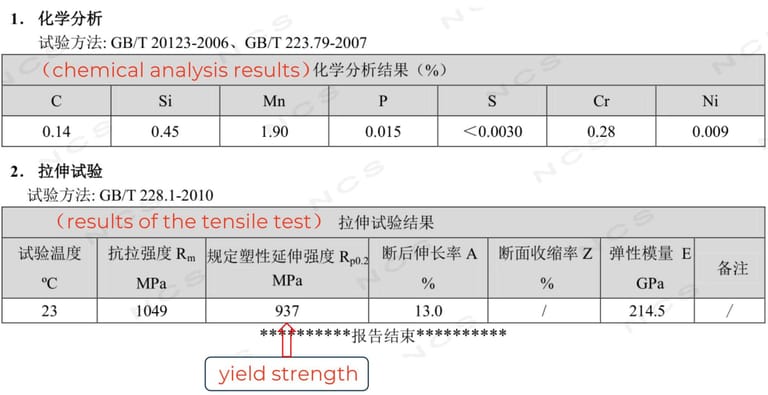

Special light steel formwork is made of Q700 high-strength steel, featuring high strength yet light weight as its most prominent advantage.The high-strength steel formwork is composed of four parts: the panel, the side ribs, the end ribs and the reinforced square tubes. The zhuniu high-strength steel formwork has the characteristics of high strength, large combined stiffness, high precision in plate manufacturing, tight joint seams, being not easy to deform, a large number of turnover times, high utilization rate, good integrity of the formwork, and strong seismic resistance.

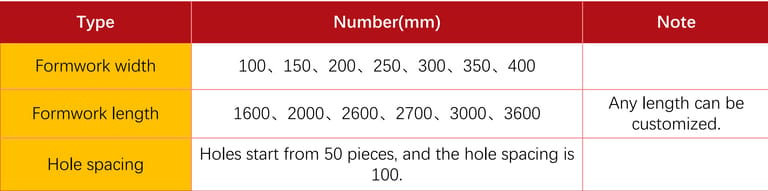

Common Size:(any size and any brand can be customed for our valued customers)

Key Indicator

Advantage :

Low Weight, Easy Transportation

One of the most immediate benefits of light steel formwork's low weight is in transportation. In large - scale construction projects, the cost and difficulty of transporting construction materials can be a significant part of the overall project budget. Light steel formwork, being much lighter than traditional heavy - steel formwork, requires less fuel for transportation. For example, in a high - rise building project in a busy urban area, where every trip to the construction site is carefully planned due to traffic restrictions, the use of light steel formwork reduced the number of truckloads needed to transport the formwork by almost 30% compared to using heavier alternatives. This not only saved on fuel costs but also minimized the time spent on transportation, allowing the construction project to progress more smoothly.

Moreover, the lighter weight of light steel formwork makes it easier to handle during loading and unloading. Specialized heavy - duty equipment is not always required, which can be a great advantage in areas where such equipment is scarce or expensive to rent. In a remote infrastructure project in a mountainous region, the construction team was able to transport the light steel formwork using standard trucks and local labor, as the formwork could be easily lifted and loaded without the need for large - scale cranes. This adaptability to different transportation conditions is a key advantage that contributes to the overall cost - effectiveness of construction projects.

Durability

Light steel formwork is renowned for its high strength, which is a crucial factor contributing to its durability. The steel used in its construction is engineered to withstand a wide range of stresses and strains that occur during the construction process. Whether it is the pressure exerted by wet concrete during pouring, the impact from construction tools, or the vibrations from heavy machinery, light steel formwork remains resilient.

In a high - rise construction project in a coastal area, the light steel formwork was exposed to strong winds, heavy rain, and high humidity for an extended period. Despite these harsh environmental conditions, the formwork maintained its structural integrity. The high - strength steel resisted corrosion and deformation, ensuring that the concrete structures being formed were of the highest quality. This durability not only reduces the need for frequent replacements but also contributes to the overall long - term performance of the building.

Compared to traditional wooden formwork, which can warp, rot, or be easily damaged by moisture and insects, light steel formwork offers a much more reliable solution. Wooden formwork may need to be replaced several times during a medium - sized construction project, while light steel formwork can serve throughout the project without significant degradation in performance.

Safety

The high strength of light steel formwork plays a vital role in ensuring construction safety. During construction, the formwork is required to support the weight of the wet concrete and withstand various dynamic loads. Light steel formwork, with its superior strength, can handle these heavy loads with ease. In a large - scale infrastructure project, such as the construction of a bridge, the light steel formwork was used to support the massive concrete sections of the bridge deck. The high - strength formwork remained stable under the extreme weight and pressure, preventing any potential collapse or deformation.

This stability and strength of the light steel formwork provide a safe working environment for construction workers. When workers are confident that the formwork beneath them is sturdy and reliable, they can focus on their tasks without the constant worry of a potential structural failure. In contrast, if a less - strong formwork were to be used, even a minor overloading or unforeseen stress could lead to a dangerous situation. For example, in some cases where traditional formwork materials have been used, collapses have occurred during concrete pouring, resulting in serious injuries or even fatalities. Light steel formwork, with its high - strength characteristics, significantly reduces the risk of such accidents, making construction sites safer for everyone involved.

Cost - effectiveness

One of the most significant aspects of light steel formwork's permanent turnover use is its remarkable cost - effectiveness over the long term. Traditional formwork materials, such as wooden formwork, have a relatively short lifespan. For example, in a medium - sized construction project, wooden formwork might need to be replaced every few uses due to wear and tear, damage from moisture, or the natural degradation of the wood. Each replacement involves not only the cost of purchasing new wooden materials but also the labor costs associated with removing the old formwork and installing the new one.

In contrast, light steel formwork can be used repeatedly for a large number of construction cycles. In a high - rise building project that spanned several years, the light steel formwork was reused over 50 times. The initial investment in light steel formwork may be higher than that of some traditional formwork materials, but when the cost is amortized over multiple uses, the unit cost per use becomes extremely low. This long - term cost - effectiveness makes light steel formwork an attractive option for construction companies looking to manage their budgets more efficiently.

Matching Accessories

The internal corner formwork and the external corner formwork are the formworks used at the corners of building structures. Such formworks are required for the corners of walls, the corners where walls meet beams, the corners where beams meet slabs, and other similar parts. The formworks are connected with dowel pins.

Method

Application

Light steel formwork is applicable to the shaping of walls, columns and beams, and can fulfill all requirements in house construction.

conclusion

light steel formwork has emerged as a revolutionary solution in the construction industry, bringing with it a trifecta of remarkable advantages: low weight, high strength, and permanent turnover use.

The low weight of light steel formwork streamlines transportation, reducing both costs and logistical challenges. It also simplifies the installation process, saving time and reducing the physical strain on workers, which in turn enhances the overall construction efficiency and worker safety.

The high - strength characteristic of light steel formwork ensures its durability in the face of various construction - related stresses and harsh environmental conditions. This not only reduces the need for frequent replacements but also guarantees the safety of construction workers by providing stable support during the construction process.

The permanent turnover use of light steel formwork is a game - changer in terms of cost - effectiveness and environmental friendliness. By being reusable for a large number of construction cycles, it significantly reduces the long - term cost per use, making it an economically viable option. Moreover, its ability to minimize construction waste aligns with the global trend towards sustainable construction, making it an environmentally responsible choice.

As demonstrated by the construction cases, light steel formwork can be effectively applied in a diverse range of projects, from high - rise residential buildings to large - scale commercial complexes. Its adaptability to different project requirements and its ability to contribute to time and cost savings, as well as waste reduction, make it a highly sought - after formwork solution.

Looking ahead, as the construction industry continues to strive for greater efficiency, cost - effectiveness, and sustainability, light steel formwork is expected to play an even more significant role. It has the potential to transform the way construction projects are carried out, setting new standards for quality, safety, and environmental responsibility. With continuous innovation and development, light steel formwork is likely to become an indispensable part of modern construction, driving the industry towards a more prosperous and sustainable future.